Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2024-01-29

What are the factors that affect the price of metal shredders?

Metal shredders are the main force in recycling scrap metal in our lives. As our living standards get higher and higher, there are more and more scrap metals, so the demand for metal shredders also increases. However, price is the most concerned issue for users when purchasing equipment. When users purchase equipment, they will first check online, but they cannot find a ready answer, because as a mechanical equipment, each manufacturer has different technical levels, quality, etc. The prices are different, so the prices are different. Let’s give you a detailed analysis of the factors that affect the price of metal shredders.

First of all, the larger the model of equipment, the higher its output will be, so the production cost will be higher, and the price will naturally be higher. The second is the material selection of the equipment. If the core of an equipment is made of high-quality materials, its performance, output, service life, etc. will be higher than ordinary equipment. The manufacturer's investment in technology is also a factor that affects the price. If the quality of the equipment is good, the performance is strong and stable, and it has few repairs during use and a long service life, then the price of the equipment will naturally be on the high side, so this is why most users The reason why they are willing to choose established and experienced manufacturers.

Which metal shredder manufacturer is better and cost-effective?

Metal shredder, also called double-shaft metal shredder, is a commonly used equipment in scrap metal recycling. It is mainly suitable for recycling scrap metal such as paint buckets, gasoline buckets, cans and other metal products. With the development of society, scrap metal There are more and more, so the demand for metal shredders is also increasing. As a professional equipment for shredding scrap metal, the quality of metal shredders has become the top priority in the selection criteria. On the market There are so many shredder manufacturers, which one is better? Below, a professional metal shredder manufacturer will analyze it for you.

Take Zhengzhou Kowloon as an example. As a professional manufacturer, Kowloon has strong technology and strength. It can tailor-make suitable shredders for you according to your needs, and its quality and performance have completely reached the highest level in China. After After decades of continuous development and improvement, a complete system has been formed. Every link from material selection to production and post-production is strictly controlled. The equipment is durable, absolutely reliable, simple to operate, efficient, energy-saving and environmentally friendly. , extremely cost-effective.

What needs to be done for daily maintenance of metal shredder?

As the name suggests, a metal shredder is a mechanical device used to crush scrap metal. Its emergence greatly reduces the waste of raw materials caused by the unusable scrap metal. Users who have used metal shredders know that whether the equipment can work normally and smoothly, its daily maintenance and upkeep are particularly important. Although the failure of the metal shredder cannot be avoided, the failure rate can be reduced to a minimum. , let me share with you some methods of daily care and maintenance of metal shredders.

The maintenance and upkeep of the metal shredder should start from usual times, such as preheating when running the equipment, and then appropriately adding materials suitable for the shredder equipment. Then after the work is completed, wait until all the materials are discharged before shutting down the equipment, and clean up the remaining materials on the machine in time. The second step is to do daily maintenance and maintenance. During maintenance, pay attention to the use of lubricating oil, clean the oil stains on the equipment, check the tightening of the bolts, and check the wear of each accessory. If there is any serious wear, It must be replaced in time, and the maintenance and upkeep of the metal shredder must start from usual times, and if you persist, you can effectively extend the service life of the equipment.

Do different manufacturers of the same shredder have different prices?

I believe our users are no longer unfamiliar with the topics of the application of shredder equipment and the scope of its crushing. We have explained it in detail in many articles. In fact, many users have discovered a problem, that is, when we call different shredder manufacturers to inquire about the price of the shredder, we will find that the prices of the shredders quoted by different manufacturers are different. Why is there such a big price gap when we ask about equipment with the same output and model?

When users consult the price of shredder manufacturers, they will find that the prices of shredders from different manufacturers vary by several thousand yuan, while others vary by tens of thousands of yuan. Moreover, the price difference of larger shredder equipment will be greater. The main reason is that when different manufacturers produce shredders, they use different materials and have different costs. Naturally, the prices of the equipment also have certain differences. The choice of motor is particularly important. The motors installed by some manufacturers are not qualified products within the scope of national regulations. If the price of such a motor is low, the price of the equipment it sells will be lower. This attracts a large number of users to purchase.

Introduction to the working principle and performance characteristics of metal shredders

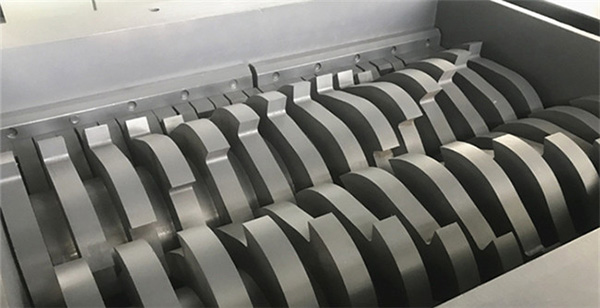

Metal shredder is a kind of equipment used to shred scrap metal products. It is a popular equipment in the field of metal recycling. It is mainly composed of blade, box, bracket, feeding system, power system, electrical system, etc. After years of research, our company's metal shredders have continuously upgraded and improved technology based on actual conditions, and also introduced advanced foreign technology concepts. They are reasonably designed and well-made, which not only extends the service life, but also improves production efficiency and reduces costs. Maintenance costs have made a huge contribution to the recycling of scrap metal in our country.

Metal shredders are used in a wide range of applications. It can be said that any metal can be shredded. The shredded materials are easy to transport, greatly reducing transportation costs. Its working principle is: the material enters the shredding box through the feeding system, and the box is loaded with a shredding blade. The material is shredded into small pieces by the shredding blade, such as tearing, squeezing, and shearing. , discharged from the lower part of the box. Finally complete the shredding of scrap metal.